Suiting Guide

Welcome to your ultimate suiting guide. Learn about how your suit should fit, a measuring and fit guide and what suit to choose for what occasion. This is your one-stop shop for finding the suit for you!

What Fit Suit Do I Need?

Regular Fit Suits

A comfortable fit across the chest, shoulders and body with straight leg trousers.

Tailored Fit Suits

Jackets have a wider fit across the chest, and trousers have more room in the thigh with a tapered hem.

Slim Fit Suits

A close fit through the shoulders, chest and waist, with trousers that are narrower through to the ankle.

Relaxed Fit Suits

A loose-fitting jacket straight leg trousers that are wider through the hips and leg.

How To Measure For A Suit?

Suit Measuring Guide

Step 1: Measure Your Chest

Measuring for a suit jacket begins with getting the chest measurement, which is the most critical for fit as this is the measurement that determines your jacket size (i.e. 40 Chest). To do this, wrap the measuring tape around the fullest part of your chest, high up under the arms. Make sure the tape is snug but not tight, and keep your arms relaxed at your sides. Take your measurement in inches.

Step 2: Measure Your Sleeve Length

Next, you’ll need to measure your sleeve length. With your arms relaxed by your side, start at the point where your shoulder meets your arm, and measure down to your wrist.

With these three measurements you’ll have the information you need to find a well-fitting suit jacket that looks great.

Step 1: Measure Your Waist

To measure for suit trousers, start with your waist measurement. Top tip: take your actual body measurements rather than over clothing. Wrap your measuring tape around your waist, which is typically just at your lower hip, just below the navel. Ensure the measuring tape is snug but not tight and take the measurement in inches.

Step 2: Measure Your Leg Length

For the length, you’ll need to take your inside leg (inseam) measurement. The inseam runs from the top of your inner thigh down to your ankle bone. Typically the trousers should fall to the top of your shoe or just slightly over. It’s best to take this measurements while standing straight. Note down your measurement in inches.

With these measurements, you’ll be well on your way to trousers that fit perfectly.

Step 1: Measure Your Chest

When measuring for a waistcoat, your chest measurement is what you will need as this will determine how the waistcoat fits across your torso. Wrap the measuring tape around the fullest part of your chest, high up under the arms, keeping it level under the arms and across the shoulder blades. Make sure it’s snug but not tight - you should still be able to breathe comfortably. Take your measurements in inches.

With accurate an chest measurement, your waistcoat will provide a sleek and polished layer to your suit.

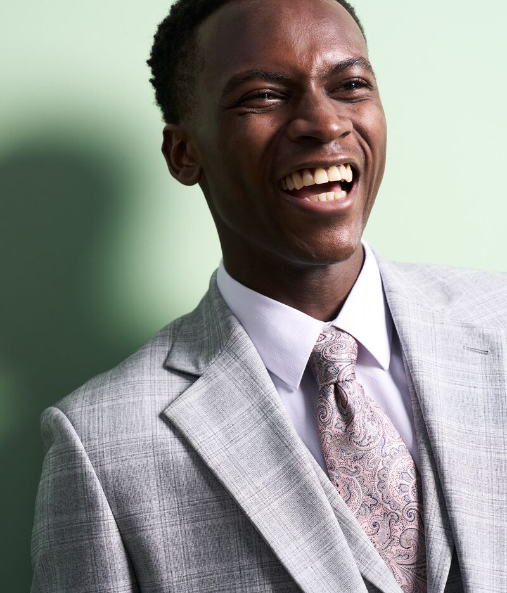

What Style Of Suit Should I Pick?

Learn about the different styles of suits on offer to determine which one you want to go for. This might be dependent on the occasion or just personal preference.

Tuxedos

The tuxedo, or dinner suit, is considered formal attire that would be worn to black-tie events. They often come in dark colours and are characterised by their satin lapels. They are usually paired with a white shirt and bow tie to achieve an elegant look.

2 Piece Suits

A 2 piece suit is a suit consisting of just a blazer and suit trousers. They come in range of fits and colours making them a versatile option for every occasion. Pair them with a shirt, tie and shoes of your choice. An easy option for those starting their suiting journey.

3 Piece Suits

A 3 piece suit is a suit consisting of a blazer, waistcoat and suit trousers. Like a 2 piece suit, they come in a range of fits and colours so you’ll be able to find one to suit you. 3 piece suits look amazing at weddings, the races or any other formal occasion.

Italian Suits

Our Italian Suits are suits made from high-quality Nova Fides fabrics from Prato, Italy. Combining clean lines and modern tailoring, these suits are of great quality at great value prices.